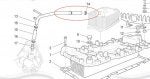

Called a Maserati Parts Place and they show two types of solid lines(hoses) above the transmission that burst on our cars over time. Apparently the Intake manifold must come off to fix or drop transmission to get to it. Mine has not ruptured yet and was figuring out how to replace it while my intake is off for a bad Alternator.

The parts place said my engine number falls into the category of the improved one piece solid metal line vs the old style that has solid metal lines connected by the dreaded 3" rubber hose that tends to burst.

I was wondering if you had yours fail did your Engine number fall between #145106 to 156873

I know it's hard to figure your engine number but your local dealer can get it off your Vin number.

part 32 vs part 40 on diagram

Thanks

The parts place said my engine number falls into the category of the improved one piece solid metal line vs the old style that has solid metal lines connected by the dreaded 3" rubber hose that tends to burst.

I was wondering if you had yours fail did your Engine number fall between #145106 to 156873

I know it's hard to figure your engine number but your local dealer can get it off your Vin number.

part 32 vs part 40 on diagram

Thanks